This video was originally published to YouTube on 4 November 2014. (source)

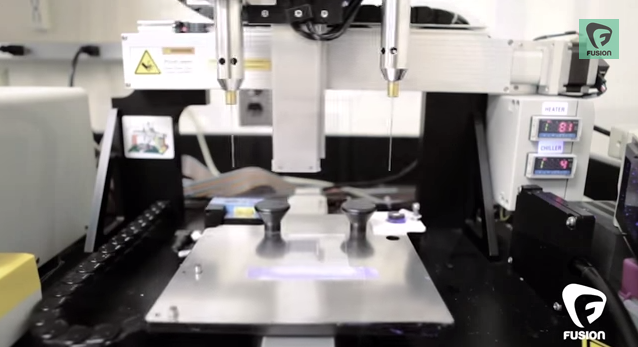

Stratasys triple-jetting technology is unique, allowing users to build products with up to three base materials in a single run, forming new Digital Materials such as Digital ABS or producing parts in vibrant colors. This technology 3D prints parts in a single, automated build with up to 80 material properties per part, ranging from rigid to rubber-like in a range of vibrant colors and a range of Shore-A values producing exceptional final-product realism.

Bringing triple-jetting workflow benefits into an office setting for the first time, the Objet260 Connex1 3D Printer achieves multi-material 3D printing with three-material parts and mixed trays in a compact system. Fewer material changeovers and hot swapping – or reloading material and support cartridges while the 3D printer is operating – allows for continuous part production.

For more information on the

Objet260 Connex1: http://ow.ly/DMvkv

The Objet260 Connex2 multi-material 3D Printer combines all of the benefits of Connex1 with the power of two-component Digital Materials. The Objet260 Connex2 multi-material 3D Printer delivers advanced multi-material prototyping and manufacturing capabilities with mixed trays of more than 100 Digital Material options; including Digital ABS, a variety of Shore A values, and a range of opacities and shades. Suitable for several applications, the Connex2 can build products with rigid, flexible and clear materials in one part. Manufacturers using Digital ABS can create mold cores and cavities for short-run injection molding or produce custom manufacturing tools like jigs and fixtures.

For more information on the

Objet260 Connex2: http://ow.ly/DMvMw

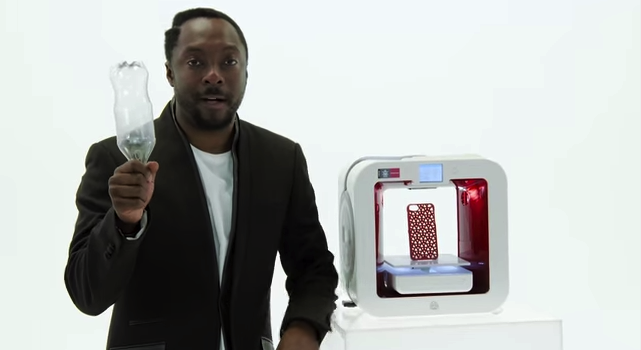

The Objet260 Connex3 is a color, multi-material 3D printer compact enough for office use. From industries such as consumer electronics requiring toughness, color and soft-touch parts, to manufactured parts in automotive combining Digital ABS with rubber-like material, Connex3 technology offers the complete range of PolyJet materials for color and maximum versatility in material properties for ultimate final-product aesthetics. Additionally, the Objet260 Connex3 will now support files exported from CAD as VRMLs, as well as STLs. This retains color designations from the designer, eliminating the need for the Connex3 operator to re-designate all shells in Objet Studio.

For more information on the

Objet260 Connex3: http://ow.ly/DMyPE

For more information on PolyJet Technology: http://ow.ly/DMyXT

For more information on Connex Systems: http://ow.ly/DMz6B